$150 triangle knife or a shin and spare tooth for forest plow

triangle knife or a shin and spare tooth for forest plow

a triangle knife or a shin and spare tooth

We are seeking partners for the export and production of firebreak plows, including forestry plows and trenching plows. Our expertise and know-how encompass the design and operation of plows used for forest reclamation. These plows can be customized for tractors of any power range; we have successfully utilized them with small tractors for work in confined areas with trees and buildings.

Establishing production for plows, shares, and spare parts is straightforward, and we have specialists ready to participate in plow manufacturing projects. Additionally, we are exploring export opportunities for plows, spare parts, and shares for forestry and trenching plows to Latin American countries.

The forestry root-cutting plow, or root-cutting plow, is an essential tool in preventing the spread of low-intensity forest fires, which are the most common type. Its primary purpose is to create firebreaks that significantly slow the spread of fire and facilitate firefighting efforts.

The forestry root-cutting plow is a specialized agricultural implement equipped with powerful V-shaped cutting blades that penetrate deep into the soil. During forest plowing, these blades sever the roots of trees and shrubs, creating a trench with barren sides that lack vegetation and a fertile layer.

This trench acts as a barrier to the spread of fire across surface vegetation and tree roots. The plow’s design allows for adjustable plowing depth, which is crucial when working with different soil types and vegetation.

$150 triangle knife or a shin and spare tooth for forest plow

a triangle knife – a shin of a forestry plow

a tooth for root breaking

how forestry plow moldboards attached to the frame

$120 plowshares of different forestry plows

Firebreaks, also known as mineralized strips, are cleared of vegetation and fertile soil. Their main function is to serve as a barrier to fire spread. The root-cutting forestry plow is used to till the soil across the width of the strip, usually between 5 and 10 meters, depending on the fire hazard level.

Firebreak – mineralized strips protect the boundaries of villages and settlements. Fires can start not only in forests but also in overgrown fields, reeds, or tall dry grass and can spread into village borders. Plowing boundaries and hazardous areas is a practice used in both rural and urban settings, not just for forest protection.

In addition to root-cutting plantage plows, trenching plows are widely used in forestry for deep plowing. These plows are designed to work soil at depths of 40 to 60-70 cm. Their primary purpose is to improve soil structure, enhance water permeability, and create conditions for better tree growth.

After trenching plows are used, deep furrows and overturned soil layers remain. Trenching plows are actively employed in creating new forest plantations and restoring degraded forest areas. Deep plowing helps break up dense soil layers, improves aeration, and allows plant roots to grow more freely and deeply.

Trenching plows, like firebreak plows, can remove shrubs and trees without prior felling, and depending on the model, can cut roots of trunks up to 10 cm in diameter. This makes them suitable for working on abandoned agricultural land that has been left uncultivated for 10-15 years and where young forests have grown—often referred to as virgin and fallow lands.

The furrows left by forestry plows or trenching plows can be used for planting seedlings, and the same trenches can be utilized for irrigation, facilitating rainwater collection. These tools are vital for large-scale planting of seeds or seedlings for commercial forestry and for reclaiming deforested areas after logging.

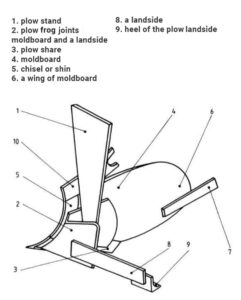

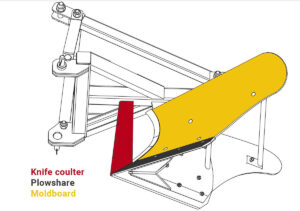

– Coulter. A small blade with a small moldboard, used for slicing the soil in general-purpose plows.

– Plow Stand. A welded vertical structure with adjustments. Plow stands are generally absent in forestry plows.

– Power Frame. Reinforced at stress points, made from high-strength steel.

– Disc Knife. Sometimes included in the design to cut roots; in some cases, a vertical knife coulter is used instead.

– Support Wheel or Skid. Prevents the plow from digging too deep, beyond what is set by the operator, and may be absent in specialized plows.

– Cutting Elements. Include chisel, share, and vertical knife. The vertical knife stands upright, the chisel may be absent, and the share cuts the soil at an angle. The share’s plane transitions into a twisted moldboard or breast. The shape and angle of twisting depend on the soil type and the plow’s intended use.

– Asymmetrical Plow. Includes a vertical plane in the body pressed against the furrow wall during operation, known as the landside, which bears significant loads.

A general-purpose plow for tilling cultivated soil will have a less aggressive moldboard curvature than one designed for virgin soil. The image may not show two elements: the landside and the plow shoe. The shoe is an angled element connecting the landside to the share and breast. In modern designs, where the body is a single welded piece, the landside, shoe, breast, and moldboard are all integrated. Only the knife and share are replaceable parts, although in some designs, only the share is replaceable.

Forestry and reclamation plows. Usually symmetrical, whereas field plows can be right-handed or left-handed. Some field plows are designed to switch between sides, but only one side is used at a time.

Forestry plows are typically symmetric, two-moldboard welded structures consisting of a frame carrying the working elements – share, moldboard, and front splitting knife or cutting wheel. The knife splits stumps, cuts sod, and pushes aside fallen trees. The shares of forestry plows are arranged at a sharp angle for root cutting, and the moldboard adds additional width to the mineralized strip.

The primary challenge in forest plowing is dealing with the soft moss and sod layer interwoven with small shrubs. This layer tends to wrap around the plow and drag along like a heap. The second challenge is large logs and stones, which require the plow to be lifted by the tractor’s hydraulic system. If the plow is designed to jump over large stumps, lifting isn’t necessary, but such a plow is not well-suited for creating mineralized strips—only for plowing for tree planting.

The cutting and power elements – shares, knives, chisels – are removable because they wear out and dull during operation and can break if they strike a boulder.

Experience shows that the service life of hardened forestry plow shares and knives is one-third longer than those made from homogeneous low-cost steel, with a price difference that more than justifies the added durability.

There are additional design considerations: the frame of a forestry plow endures significant variable loads, different from those encountered by general-purpose field plows. Therefore, frame reinforcement, strut elements, and high-quality welding are crucial in forestry plow construction.

The attachment points and elements for connecting to the tractor’s hitch are also critical. If made from standard mild steel, like ST3, A284Gr nearest material, or using ordinary bolts, operational issues such as bending are unavoidable, making field repairs difficult.

Some forestry plows feature complex designs developed in the Soviet Union but are no longer produced in Russia, such as auger designs.

These are currently available and consist of two large, sharp, heavy discs mounted on a sturdy frame, rotating on a protected bearing at an angle to the direction of pull. The disc edge cuts the soil, and the curved surface of the rotating disc functions as a moldboard, forming and turning the soil layer.

***********

Trench plough, deep plow, reforestation plow, subsoil plough, trenching plough, trenching plow, deep draining plow, heavy plow, plow ditcher, reclamation plow – all this descriptions are similar to forest plow, utilised to make firebreak trench and to make trenches for young trees seedlings, or make deep trench to lower water level – drainage.

Ready to start your project? Call us today and let’s discuss how we can bring your vision to life with our experience and professionalism. In company with Parcela Construccion, you can make the process of preparing a plot of land efficient and affordable.